Table of Contents

THE CONTEXT: It is estimated that 62 million tonnes of Bio-CNG, also known as Compressed Biogas (CBG) can be produced in India every year from various sources. To tap this, Ministry of Petroleum and Natural Gas (MoPNG) recently announced that 5,000 CBG plants will be set up by 2025 that will produce 15 million tonnes of CBG. The following article attempts to analyse the key issues and potential attached to the production of Compressed Biogas (CBG).

WHAT IS COMPRESSED BIOGAS (CBG)?

Compressed biogas (CBG) is a form of renewable natural gas (RNG) that is produced by the anaerobic digestion of organic matter, such as agricultural waste or sewage. The gas produced by this process, known as biogas, is composed primarily of methane and carbon dioxide. After being cleaned and compressed, it can be used as a transportation fuel, or as a substitute for natural gas in various industrial and commercial applications. CBG is considered a renewable energy source because the organic matter used to produce it is continuously replenished, and because its use reduces greenhouse gas emissions compared to fossil fuels.

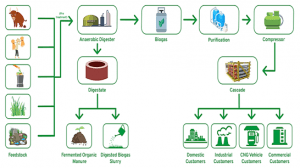

Process of producing Compressed biogas (CBG)

- Waste / Bio-mass sources like agricultural residue, cattle dung, sugarcane press mud, municipal solid waste and sewage treatment plant waste, etc. produce bio-gas through the process of anaerobic decomposition. The bio- gas is purified to remove hydrogen sulfide (H2S), carbon dioxide (CO2), water vapor and is compressed as Compressed Bio Gas (CBG), which has methane (CH4) content of more than 90%.

- CBG has calorific value and other properties similar to CNG and hence can be utilized as green renewable automotive fuel. Thus, it can replace CNG in automotive, industrial and commercial areas, given the abundance biomass availability within the country.

- Conversion of agricultural residue, cattle dung and municipal solid waste (MSW) into CBG in a commercial scale is expected to have the following benefits:

o Import reduction of natural gas and crude.

o Using agricultural residue, cattle dung and MSW for the production of CBG and thus, to achieve reduction in emissions and pollution.

o A boost towards fulfillment of National commitments in achieving climate change goals.

o Providing a buffer against energy security concerns and crude/gas price fluctuations.

o Contribution towards Swachh Bharat Mission through responsible waste management

o Lowering pollution and carbon emission.

o Providing additional source of revenue to the farmers, rural employment and amelioration of the rural economy.

o The slurry left after biogas is extracted from the digester is passed through a solid-liquid separator. The solid part is cured in the open for 10-15 days and makes for carbon-rich organic manure, while the liquid part can also be used as liquid fertilizer.

- The biogas produced contains approximately 55% to 60% methane, 40% to 45% carbon dioxide and trace amounts of hydrogen sulphide. Biogas is purified to remove carbon dioxide and hydrogen sulphide gases to prepare CBG. The CBG can be transported through cylinder cascades or pipelines to retail outlets.

SATAT (SUSTAINABLE ALTERNATIVE TOWARDS AFFORDABLE TRANSPORTATION)

SATAT (Sustainable Alternative Towards Affordable Transportation) scheme is a government initiative in India launched by the Ministry of Petroleum and Natural Gas to promote the production and use of compressed biogas (CBG) as a transportation fuel. ‘SATAT’ scheme on Compressed Bio Gas (CBG) was launched on 1.10.2018. The scheme aims to establish a network of Compressed Bio-Gas (CBG) production plants across the country and to make CBG available to customers at a competitive price.

Key features of SATAT:

- The scheme envisages targeting production of 15 MMT (million tons) of CBG by 2023, from 5000 Plants.

- The initiative aims to produce compressed biogas (CBG) from Waste and Bio-mass sources like agricultural residue, cattle dung, sugarcane press mud, Municipal Solid Waste (MSW) and sewage treatment plant waste.

- Under SATAT scheme, entrepreneurs shall set up CBG plants, and produce & supply CBG to Oil Marketing Companies (OMCs) for sale as automotive & industrial fuels. PSU OMCs will be inviting Expression of Interest (EoI) from potential entrepreneurs to set up CBG plants under SATAT scheme, and supply CBG to OMCs for sale as automotive & industrial fuel.

- SATAT initiative offers an efficient solution for the treatment and disposal of municipal solid waste management and help in tackling the problem urban air pollution due to farm stubble burning. It will boost entrepreneurship, rural economy and employment and provide an additional source of revenue to farmers.

The potential of the SATAT scheme is that it can help in achieving several important goals:

- Reducing dependence on fossil fuels: By promoting the use of CBG as a transportation fuel, the SATAT scheme can help reduce India’s dependence on fossil fuels, which will have positive impacts on the environment and the economy.

- Creating new jobs: The SATAT scheme has the potential to create new jobs in the production, distribution, and use of CBG, which will help to boost economic growth and employment.

- Improving air quality: As CBG is a clean-burning fuel, using CBG as a transportation fuel can help improve air quality in cities and towns across India, which will positively impact public health.

- Promoting rural development: The SATAT scheme can help to promote rural development by providing farmers and rural communities with new income opportunities through the production and sale of CBG.

OTHER GOVERNMENT STEPS

There are several government policies and programs in place in India to promote the production and use of compressed biogas (CBG):

- National Biogas and Manure Management Programme (NBMMP): This program, launched by the Ministry of Non-Renewable Energy, provides financial assistance and technical support to farmers and other stakeholders for the construction and operation of biogas plants.

- National Action Plan on Climate Change (NAPCC): The NAPCC includes a target to increase the share of biogas in the energy mix and to promote the use of biogas as a transportation fuel.

- National Clean Energy Fund (NCEF): The NCEF provides financial assistance for developing clean energy technologies, including biogas.

- National Mission on Biogas and Organic Manure (NMBOM): The National Mission on Biogas and Organic Manure (NMBOM) aims to promote the use of biogas as a clean and renewable energy source, and to increase the use of organic manure in agriculture.

- Ministry of New and Renewable Energy (MNRE): The Ministry of New and Renewable Energy (MNRE) has implemented a number of policies and schemes to promote the use of renewable energy, including biogas, in India.

- Government of India launched the Galvanizing Organic Bio-Agro Resources Dhan (GOBAR-DHAN) scheme to convert cattle dung and solid waste in farms to Bio-CNG (CBG) and compost. GOBAR-DHAN scheme proposes to cover 700 projects across the country in 2018-19.

- Officially designated as fermented organic manure (FOM) in 2021, the waste product from CBG plants was incorporated in the Fertilizer (Inorganic, Organic or Mixed) (Control) Order, 1985. The Ministry of Fertilizers, through an order in May 2022, made it mandatory for fertilizer companies to offtake FOM from CBG companies under SATAT as part of Integrated Nutrient Management.

Overall, these policies and programs aim to increase the availability of feedstock, improve technology and infrastructure, reduce costs, and increase awareness and understanding of the benefits of CBG in India.

Case study: The Indore municipal commission (IMC)

- Indore, is not just managing waste, but also earning revenue from user fees, carbon credits and also fines for non-segregated waste.

- In 2020, IMC earned Rs 9,239 lakh in revenue from user charges, while the expenditure was 8,190.66 lakhs. For Indore, the CBG plant came five years after putting its waste segregation infrastructure in place.

- Apart from collecting segregated waste at source in compartmentalized vehicles, Indore has transfer stations where waste collected in six separate categories is further sorted and transported in separate colour-coded capsules to the processing facilities for wet and dry waste.

- The coming together of political, administrative and public will is what has worked for Indore, which is missing in metros like Delhi that have set up waste-to-energy plants in the name of processing even though only 11 per cent of the city waste is worth incineration.

ISSUES FACED IN BIO CNG PRODUCTION

India faces several challenges in the production of compressed biogas (CBG), including:

- Lack of sufficient feedstock: India has a shortage of suitable feedstock for biogas production, such as agricultural waste and sewage, which limits the potential for CBG production.

- Limited technology and infrastructure: India have a limited number of biogas plants and the technology used in these plants is often outdated, which makes it difficult to achieve large-scale CBG production.

- High costs: The cost of building and operating biogas plants in India is relatively high, which makes it difficult for small and medium-sized farmers to participate in CBG production.

- Limited awareness and understanding: There is limited awareness and understanding of the benefits of CBG and how to produce it among farmers, policymakers, and other stakeholders in India.

- Government policies: Despite a number of government policies and schemes in place, implementation of the same is not effective and not enough to promote CBG production in India.

- Limited Distribution infrastructure: India lacks the necessary infrastructure to transport and distribute CBG to end-users, making it difficult to expand its use as a transportation fuel or as a substitute for natural gas.

- Quality issues: The quality of biogas produced in India often does not meet the standards required for use as a transportation fuel or for injection into the natural gas grid, which limits its potential uses.

- Lack of proper waste segregation: The feedstock for MSW-based CBG plants is source-segregated waste also its biggest challenge. Badly segregated waste can lead to construction and demolition waste or other hard particles entering the digester, reducing its energy efficiency and damaging it.

Overall, India needs to work on increasing feedstock availability, improving technology and infrastructure, reducing costs and increasing awareness, and addressing the distribution infrastructure, Government policies and quality issues in order to increase the production of compressed biogas.

THE WAY FORWARD

- Increasing the availability of feedstock: India can increase the availability of feedstock by promoting the cultivation of energy crops such as Jatropha and Pongamia, as well as by encouraging the use of agricultural and municipal waste as feedstock for bio-CNG production.

- Improving the efficiency of bio-CNG production: India can improve the efficiency of bio-CNG production by investing in research and development to enhance feedstock conversion into bio-CNG, as well as by implementing best practices in the production process.

- Developing infrastructure for bio-CNG distribution: India can develop infrastructure for bio-CNG distribution by building more bio-CNG refueling stations and by making bio-CNG more easily accessible to consumers.

- Encouraging private sector investment: India can encourage private sector investment in bio-CNG production by providing financial incentives and creating a favorable policy environment for bio-CNG production.

- Encouraging the use of bio-CNG in transportation sector: India can encourage the use of bio-CNG in the transportation sector by promoting the use of bio-CNG vehicles and by providing incentives for the conversion of existing vehicles to run on bio-CNG.

- Promoting awareness: India can promote awareness of bio-CNG as a cleaner and more sustainable alternative to fossil fuels, to encourage more people to adopt it.

- Learning from global examples: Countries such as Germany, Italy, UK, France and Switzerland are promoting bio-gas usage promoted by supporting legal frameworks, education schemes and the availability of technology. Biogas produced in European countries is mostly fed into local natural gas grids and used for power generation. Grid injection is most common in European states followed by vehicles fueled with biogas (either pure or in blend with natural gas) and biogas is also used for heating purposes either directly or blended to natural gas. India should also assess such utilities of biogas in India to ensure completion of its commitments under INDCs, etc.

THE CONCLUSION: India is among the fastest growing economy in the world and its energy consumption is slated to increase rapidly. India’s dependence on fossil fuels for its energy needs has two major concerns i.e., a growing import bill and the carbon emission. The country now imports nearly 85 per cent of crude, which roughly translates to 45% of primary energy demand and will only go up in the near future. There should be more focused implementation of policies like SATAT, which by producing CBG from wastes, would not only meet the growing energy demand in a responsible and eco-friendly manner, but also contribute to India’s commitment to GHG emission reduction.

Questions

- “In 2021, there were only 3,180 CNG stations in India compared to more than 65,000 petrol pumps.” In such a scenario, highlight the challenges faced in moving towards greener fuels like Bio-CNG in India and suggest how India could achieve its ambitious low carbon economy dream in the future.

- The SATAT (Sustainable Alternative Towards Affordable Transportation) scheme is said to be a game changer in the production and use of compressed biogas (CBG) in India. Examine critically.