Answer.

APPROACH

Introduction- Define critical elements and support with relevant examples. Highlight their growing significance due to varied applications.

The Body

- Briefly address the use of critical elements in electric vehicles.

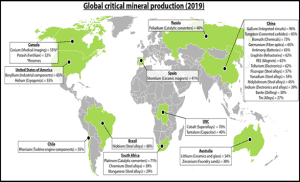

- Discuss the global distribution of these resources-must draw an associated world map.

- Elaborate on the challenges associated.

Conclusion- Mention what measures India should take to enhance resilience in critical minerals supply. Brief what initiatives India has taken to secure the supply of these critical minerals.

Introduction:

Critical minerals are defined as those elements that are the building blocks of modern-day technologies in the era of Industrial Revolution 4.0 and are at the risk of supply chain disruptions. Examples include graphite, lithium, cobalt, silicon, antimony, rare earths etc. With their application in the manufacturing of batteries for electric vehicles, magnets, computer chips, aerospace, communication and defence industries, countries throughout the globe have been focused on securing these critical elements for smooth and faster economic development.

Critical minerals are defined as those elements that are the building blocks of modern-day technologies in the era of Industrial Revolution 4.0 and are at the risk of supply chain disruptions. Examples include graphite, lithium, cobalt, silicon, antimony, rare earths etc. With their application in the manufacturing of batteries for electric vehicles, magnets, computer chips, aerospace, communication and defence industries, countries throughout the globe have been focused on securing these critical elements for smooth and faster economic development.

The Body:

The efforts towards decarbonisation of the transportation sector necessitate the transition towards green, clean transportation, which underscores the significance of electric vehicles, which in turn increases the demand for critical elements.

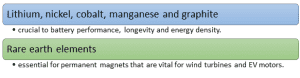

Critical elements used in Electric mobility:

GLOBAL DISTRIBUTION OF CRITICAL ELEMENTS:

1. South Africa and Kazakhstan are rich in minerals such as chromium.

2. The critical elements from the platinum group are majorly concentrated in Russia, Ukraine, and South Africa.

3. Brazil holds the maximum reserves of Niobium (over 90%).

4. More than half of the Helium and beryllium reserves are found in the

5. South Africa and Kazakhstan are rich in minerals such as chromium.

INDIA:

1. Over 60% of the cobalt reserves are concentrated in the states of Odisha, followed by Jharkhand and Nagaland.

2. Nickel is found in the Jaduguda and Singhbhum regions of Jharkhand, besides the Jajpur, Keonjhar & Mayurbhanj districts of Odisha.

3. The lithium reserves have been discovered recently in Jammu and Kashmir.

CHALLENGES IN THEIR EXPLORATION AND UTILIZATION:

1. Inadequate reserves in India: India lacks adequate reserves of critical elements, which increases its dependency on imports from resource-rich countries such as China and USA. India, in order to manufacture renewable energy technologies and transition to electric vehicles, would require increasing quantities of critical minerals, which raises concerns regarding demand-supply mismatch.

2. Quality concerns: Indian resource is significantly lean w.r.t. grade, and it is tied with radioactivity making the extraction long, complex and expensive. Further, Indian resources contain Light Rare Earth Elements (LREE), while Heavy Rare Earth Elements (HREE) are not available in extractable quantities.

3. The dominance of China: Over 60% of major critical minerals are under the control of China, a rival regional power for India. This complicates the situation for India, which has a trade deficit with China. China also holds control over reserves of DRC, further adding to supply constraints for India.

4. Supply-side constraints: The high dependence of India on imported critical elements raises apprehensions of short supply and unpredictable price hikes in raw materials for its industries.

-

-

- Pandemic: The semiconductor chip shortage during the COVID-19 pandemic impacted the Indian industry adversely and underscored the importance of diversification of import options as well as the need for indigenous exploration and production of feasible critical minerals.

- Ukraine-Russia War: India struggles to assure resilient supply of critical minerals from Russia and Ukraine which have been blessed with abundant reserves of critical minerals like lithium, cobalt, graphite, titanium, tantalum, niobium, beryllium, palladium etc.

- Russia-China Bonhomie: The change in the balance of powers due to the strategic partnership between China and Russia would further add to problems for India in securing the vital critical minerals it needs for ushering in its industrial growth.

- Exclusion from Partnership Strategies: The developed countries have forged strategic partnerships such as Mineral Security Partnership and G7’s Sustainable Critical Minerals Alliance. Developing countries, including India, have missed out.

-

5. Technological barriers: The Indian rare earth industry mainly focuses on its downstream production process while the upstream processes are ignored, given the higher environmental risks involved and the need for advanced technologies. India lags behind in advanced technology to economically explore and extract the rare earth elements.

6. Limited Private Sector Participation- India’s failure to encourage entrepreneurship in this sector of the economy adds to costs and increased reliance on public companies. The sector was largely reserved for the public sector, which delayed the progress of India in the extraction and production of the available critical minerals in the country.

Also, the industries find it easy to procure cheaper raw materials from China, which disincentives the private Indian companies to invest in the production of rare earth elements.

7. Policy Paralysis- India set up an exclusive firm, namely Indian Rare Earth Ltd(IREL), in 1950, but the cumbersome, time-consuming environmental clearances, hurdles in obtaining licenses, inadequate dispute resolution mechanism and unclear policies delayed the production of such minerals.

Mining of Rare Earth Elements is further constrained due to CRZ regulations, Mangroves, Forests and inhabitation.

Conclusion:

A national critical minerals strategy with a focus on priority concerns in supply risks, domestic policy regime, sustainability, foreign collaborations and listing of identified critical minerals in the Mines and Minerals (Development and Regulation) Act 1957 is required. The government of India has taken proactive steps to secure the supply of critical minerals by establishing Khanij Bidesh India Limited (KABIL) and concluding a 3-year India-Australia Critical Minerals Investment Partnership.

Spread the Word